IXPE foam liner

IXPE foam cushion, with its excellent waterproof, moisture-proof and impact resistance, brings extra comfort to the floor. It is not only suitable for SPC and LVT flooring, but also a perfect partner for wall panels, adding peace of mind and harmony to your home environment.

IXPE foam cushion, with its excellent waterproof, moisture-proof and impact resistance, brings extra comfort to the floor. It is not only suitable for SPC and LVT flooring, but also a perfect partner for wall panels, adding peace of mind and harmony to your home environment.

IXPE foam, namely irradiated cross-linked polyethylene foam, is an excellent sound insulation material, suitable for matching with SPC floor, LVT floor, PVC floor and even wood floor. This foam is composed of ultra-fine, high-density, closed cell structure and cross-linking characteristics, which can improve the mute effect and comfort of the floor. At the same time, it also has excellent moisture-proof and shock-absorbing functions, which help improve the overall user experience of the floor and extend its service life.

IXPE pad is designed specifically for the bottom layer of our SPC flooring. It not only perfectly fits SPC flooring, but can also be used alone to match other floor or wall covering materials. This pad has excellent cushioning performance and stability, which can effectively reduce noise, provide comfortable foot feel, and also have a certain moisture-proof and anti slip effect. Whether used in commercial or residential environments, IXPE liners can provide additional protection and aesthetic effects for floors or walls.

IXPE pad advantages

1. Excellent moisture resistance. The material we use is IXPE, namely irradiated cross-linked polyethylene, which is a foam material with closed cell structure. This material has 100% waterproof performance, which can effectively prevent moisture infiltration, thereby avoiding the growth and invasion of mold, decay, and bacteria, ensuring the long-term stability and service life of the product.

2. The noise reduction effect is significant. IXPE material has an ultra-fine and unique structure, which endows it with excellent seismic and noise reduction performance. Whether in home environments or industrial applications, the use of IXPE materials can significantly reduce noise and provide a quieter and more comfortable living and working space.

3. Excellent thermal conductivity. IXPE material not only performs well in sound insulation, but also has excellent thermal conductivity. This makes IXPE not only suitable for sound insulation needs, but also an ideal material for winter floor heating systems. It can effectively conduct heat, keep the ground warm, and improve living comfort.

4. Excellent environmental performance. IXPE material is non-toxic, odorless, has extremely low radiation levels, and is friendly to human health and the environment. In addition, it also has 100% recyclability, which conforms to modern environmental protection concepts and reduces the burden on the environment, making it an ideal choice for sustainable development.

5. The installation process is fast and easy. The die-cutting, slitting, and composite process of IXPE material with other materials are very simple, which greatly simplifies the installation process. Both professional installation teams and ordinary users can easily and quickly complete installation work without the need for complex tools and techniques, greatly saving time and costs.

Floor installation

1.Before installing the floor, it is necessary to thoroughly clean the surface of the underlying floor to ensure that it is clean, dust-free, and in a dry state. This step is crucial as any moisture or dirt can affect the installation effect and service life of the floor.

2. Next, carefully lay IXPE foam liner along the wall edge. These pads not only provide additional cushioning, but also ensure a certain gap between the floor and the wall, avoiding expansion or contraction caused by temperature changes. When laying pads, make sure they are flat and tightly attached to the wall to avoid any warping or loosening.

3. Then, unfold the first volume of IXPE foam cushion and place it beside the cushion. During the laying process, it is important to ensure that the cushion layer maintains an appropriate distance from the wall and does not come into direct contact with it. Next, spread the second volume of IXPE foam cushion next to the first volume, and be careful not to overlap the two volumes of cushion. To ensure the sealing effect at the joint, it is necessary to carefully stick specialized tape along the joint to ensure that it is firm and seamless.

4. In this way, continue to lay the next IXPE foam cushion until the entire floor area is covered. Every time a roll of cushion is laid, it is necessary to carefully check whether the joints are flat and firmly adhered together. This can ensure the flatness and stability of the entire floor, avoiding warping or loosening problems during future use.

5. Finally, after completing the laying of all cushion layers, conduct a comprehensive inspection to ensure that all joints are firmly sealed and there are no omissions or loose areas. In this way, the floor installation work is completed. Through meticulous preparation and laying process, the service life and effectiveness of the floor can be ensured to reach the best state.

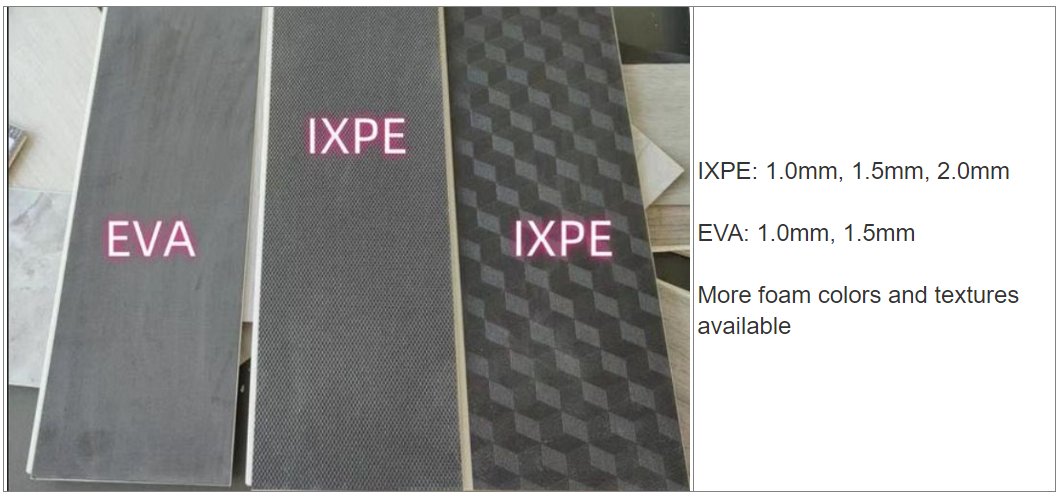

Specifications

Material: closed cell cross-linked PE foam.

Thickness: 1 millimeter -6 millimeters. The commonly used thicknesses are 1.0 millimeters and 1.5 millimeters.

Width: 1-1.5 meters, maximum 1.8 meters. The commonly used widths are 1.0 meter and 1.5 meters.

Length: 8.45 meters, 16.9 meters or customized.

Colors: Black, Green, Blue, Grey, Orange, and other RAL colors

Density: 67 kilograms per cubic meter, 100 kilograms per square meter, etc.

Coating process: PE film, silver film, aluminum foil or other.

Jadelight recommends high-quality SPC flooring and IXPE soundproof mats

|

|