Application and Advantages of Steel-Based and Wood-Based Antistatic Flooring

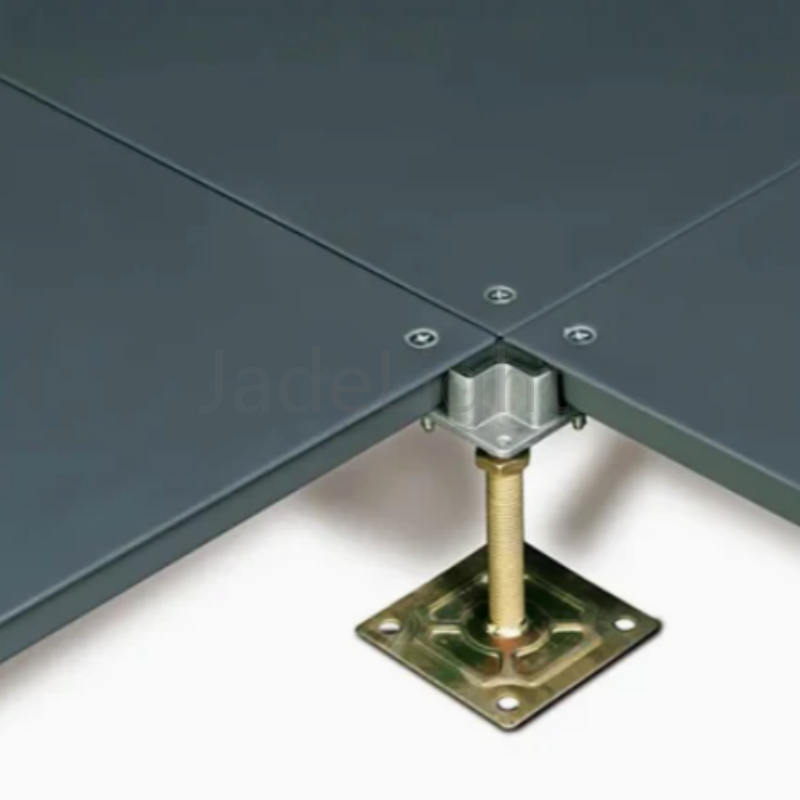

In modern office environments, antistatic flooring has become the preferred material for more and more companies and institutions when building data centers, computer rooms, offices and other places because of its protective effect on electronic equipment and office facilities. Antistatic flooring can not only effectively prevent static electricity accumulation, but also provide convenience for ground wiring and ventilation. This article will focus on several common types of raised floors, including OA500 steel-based network flooring, OA600 steel-based network flooring, 600 steel-based antistatic flooring, calcium sulfate antistatic flooring, wood-based antistatic flooring and ventilation flooring, and analyze their characteristics and applications.

1. OA500 steel-based network flooring

OA500 steel-based network flooring uses high-quality steel plate as the base material, and the surface is covered with antistatic material, which has high strength and stability. This type of flooring is usually used for computer equipment and network wiring in office environments. The advantages of OA500 steel-based network flooring are its good load-bearing capacity and antistatic performance, which can effectively avoid the damage of static electricity to equipment and personnel. In addition, the steel-based floor has good fireproof performance and strong pressure resistance, which can effectively ensure the safety of equipment.

2. OA600 steel-based network floor

The OA600 steel-based network floor has further improved its load-bearing capacity and anti-static performance based on OA500. The OA600 steel-based floor uses thicker steel plates as the base material, which enables it to maintain stable performance even under high load conditions. The OA600 steel-based floor is suitable for environments with large loads and frequent wiring, such as large computer rooms and data centers. Its sturdy and durable characteristics can withstand the weight of a variety of equipment and ensure that the floor will not deform after long-term use.

3. 600 steel-based anti-static floor

The design focus of the 600 steel-based anti-static floor is its anti-static property and load capacity. It uses galvanized steel plates or cold-rolled steel plates, and the surface treatment uses anti-static coating, which can effectively prevent static electricity from damaging the equipment. This type of floor is commonly found in places where there are many electronic devices and greater static hazards, such as server rooms and electronic manufacturing plants. In addition, 600 steel-based anti-static flooring also has high wear resistance and can withstand long-term use and heavy equipment.

4. Calcium sulfate anti-static flooring

Calcium sulfate anti-static flooring is an environmentally friendly flooring that uses calcium sulfate board as the core material and is coated with an anti-static layer on the surface. Calcium sulfate flooring has a good anti-static effect, and its hardness is high and its pressure resistance is strong, which is suitable for environments with strict anti-static requirements. In addition, calcium sulfate flooring also has good moisture and fire resistance and a long service life. Due to its light material, this type of floor is more convenient to install and is suitable for various modern office spaces, data centers, laboratories and other places.

5. Wood-based anti-static flooring

Wood-based anti-static flooring is based on wood and is treated with an anti-static coating on the surface, which can effectively inhibit the generation of static electricity. Compared with metal-based floors, wood-based floors have a more natural appearance and bring a warmer and more comfortable atmosphere to the office environment. It not only has anti-static properties, but also has good fire resistance and moisture resistance. Wood-based anti-static flooring is mostly used in office areas, conference rooms and some working environments with lighter equipment that require high decorative effects.

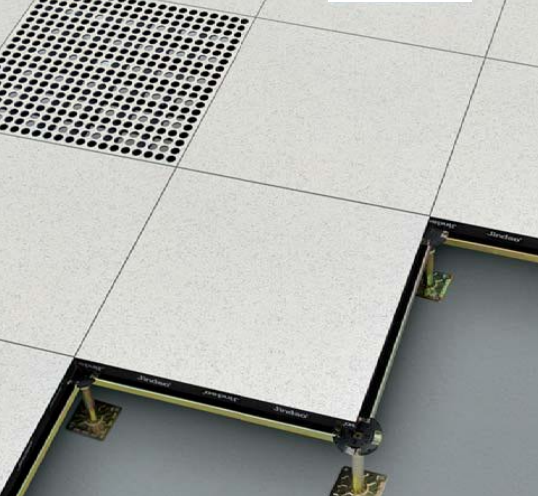

6. Ventilated floor

Ventilated floor is a common type of floor in modern data centers and computer rooms. It is usually made of metal material with certain ventilation holes on the surface. The main function of this floor is to provide air circulation for equipment to avoid overheating of equipment due to poor air circulation. Ventilated floor not only has good anti-static performance, but also can conveniently combine air conditioning, exhaust system and ground cable wiring, thereby effectively improving the temperature control and power supply efficiency of the computer room.

Selection and application of anti-static floor

When choosing a suitable anti-static floor, decisions must be made based on the specific use environment, load requirements and electrostatic protection level. For example, in an environment with high requirements for electrostatic protection, steel-based network floor and calcium sulfate floor are often preferred because of their strong anti-static function and load capacity. For office space or conference room with high appearance requirements, wood-based anti-static floor can be considered to ensure that it has both anti-static function and aesthetic requirements.

No matter which type of anti-static floor is chosen, attention should be paid to its installation and maintenance. Regularly check the electrostatic performance, load-bearing capacity and surface coating integrity of the floor to ensure that the floor is always in the best use state.

High quality raised floor recommendation

Summary

With the advancement of modern technology and the improvement of environmental protection requirements, anti-static flooring, as an important part of high-tech places such as offices and data centers, is constantly upgrading and developing. From OA500 steel-based network flooring to wood-based anti-static flooring, from calcium sulfate to ventilated flooring, each floor has its unique advantages and application scenarios. Correctly selecting and reasonably installing anti-static flooring can not only effectively avoid the harm of static electricity to electronic equipment, but also improve the comfort and safety of the working environment.